The Ocean Snake of Doom (for Plastic)

This idea has been brought to life

The Ocean Snake of Doom (for Plastic) is a very practical yet amazing invention that in fact has an incredibly positive effect on the world!

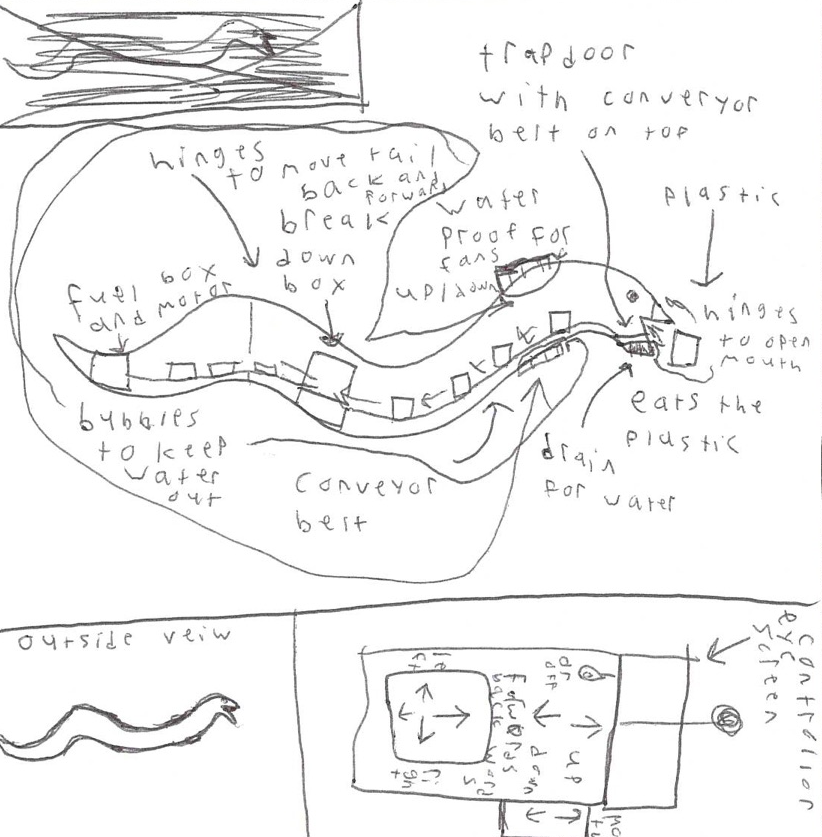

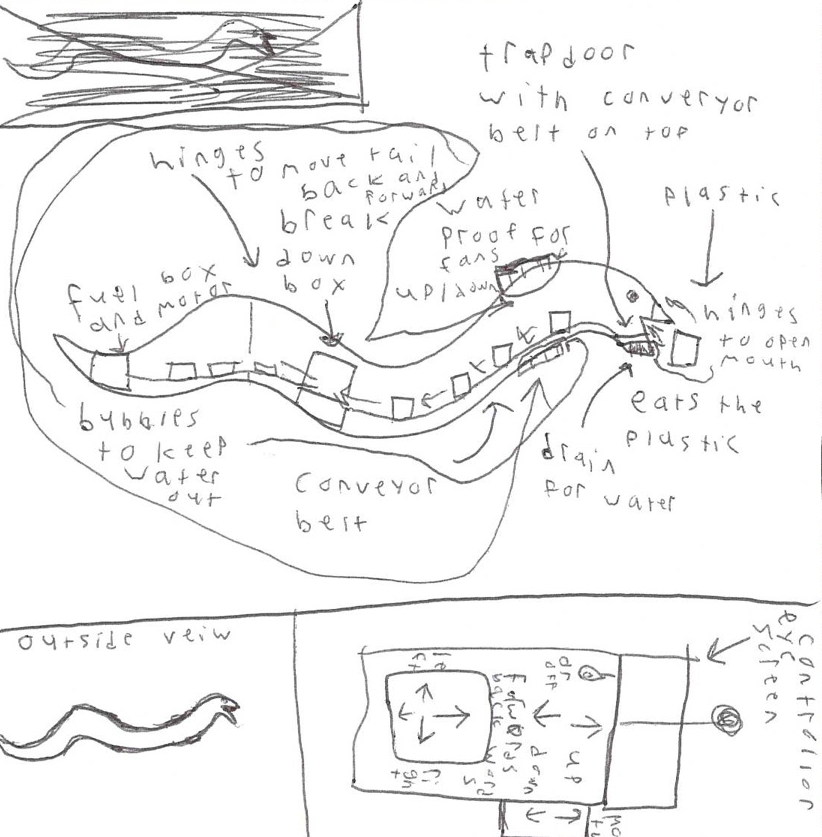

Check out Samantha's original design for the The Ocean Snake of Doom!

The Ocean Snake of Doom was invented by Samantha and brought to life by PTI Engineered Plastics Inc.a Product Design, Prototyping and Manufacturing company.

PTI Engineered Plastics Inc. says about the make...

The Team at PTI ID was intrigued by the many features of the Ocean Snake of Doom, including recycling of the trash collected...Steve and Mike researched different snakes and marine animals to provide them with "design fuel". How would The Ocean Snake of Doom's head look? What marine animals could they look to to understand how a creature moves through the water? What features on a creatures body help them move quickly through the water? There are many questions that can be answered by looking to the natural world for clues!

Take a look at the modeling of the snake! The team were working out the mechanical features such as how the snake's mouth would open to take in the trash and how the conveyor belt would function to move the plastic trash through the snake.

Look at all the details...it looks exactly like a snake with that snake skin!

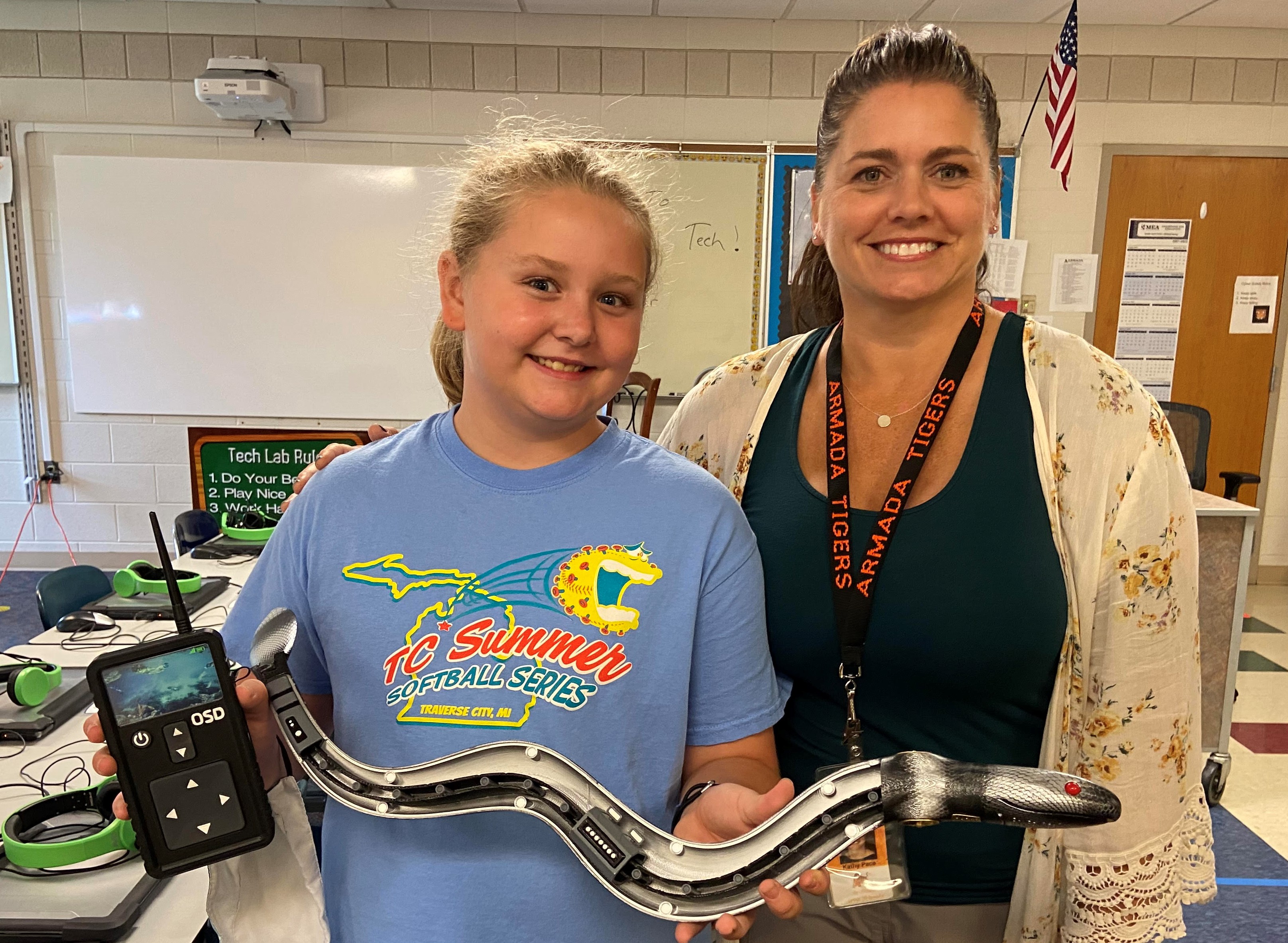

Samantha looks happy with her brought to life invention! Bring on more brilliant invention ideas!

Blog entries

Recently the Ocean Snake of Doom was revealed to our inventor, Samantha, her teacher and fellow students.

We hope Samantha and all the inventors keep dreaming big!

Even when you think you are making great progress on a project unexpected delays can and will occur! In creating the "guts" of the Ocean Snake of Doom, mainly the conveyor belt to move doomed trash, the 3D printer malfunctioned and ruined the parts.

Back to the beginning for the team!

The team has been working on the details , including the paint and texture for physical model of the Ocean Snake of Doom. Different techniques were used to recreate the look of a snake's skin, using painter's tape and mesh and layering colors of paint.

The team created a project summary to document the design process in preparation for the final physical model being made.

The PTI ID Design team is working on creating a physical model of the Ocean Snake of Doom by first 3D printing component parts. To create "lifelike" skin textures on the exterior of the model for the snake they experimented with various "everyday" materials like netting, wire mesh and drywall tape and different types of spray paint. Creating models involves using your imagination and any and all resources at your disposal!

This week our designers have developed a sketch of the Ocean Snake of Doom (OSD) controller based on Samantha's very detailed instructions. Cameras are located within the snake's eyes, so the controller is equipped with a display screen which will allow the snake's pilot to see the trash coming its way. The face of the controller has a directional keypad and buttons for maneuvering the snake up and down in the water. Buttons on the side of the controller operate the snake's mouth.

The team at PTI was excited to meet with Samantha and her teacher Kathy Pace to show them the progress they made on the Ocean Snake of Doom design!

The team continued working on modeling the snake's head and body using Solidworks, and working out the mechanical features such as how the snake's mouth would open to take in the trash and how the conveyor belt would function to move the plastic trash through the snake.

Samantha chose stainless steel to construct the Ocean Snake of Doom, the design team agreed this was a good choice of material that could hold up well in the harsh ocean environment.

Steve and Mike researched different snakes and marine animals to provide them with "design fuel". How would The Ocean Snake of Doom's head look? What marine animals could they look to to understand how a creature moves through the water? What features on a creatures body help them move quickly through the water? There are many questions that can be answered by looking to the natural world for clues!

They also looked at mechanical designs of conveyors and other manufacturing and processing processes for technical ideas.

The Team took Samantha's original design and studied the mechanical features of the snake and did a "rough" animation of the snake to understand how it might take in the plastic waste and also move through the water. They looked at where filters might be placed, how the conveyor belt would function, location of the plastic breakdown box and position of the propellers.

The Team at PTI ID got to meet Samantha the Little Inventor of The Ocean Snake of Doom!

We had a great first meeting discussing her ideas and how we would work together to bring it to life and shared some initial design inspirations from the team.

The Team at PTI ID was intrigued by the many features of the Ocean Snake of Doom, including recycling of the trash collected.

The team will first look for inspiration from the natural world to understand and develop the shape of the device, and then study the mechanics of the snake and look to existing industrial products to integrate the technical features.

The team will first collaborate on designs and modeling and then create a physical scale model of the Snake of Doom.